Beyond Surface Sealers: Nanovations 3001 Hydrophobic Agent ads Permanent Protection for Concrete, Mortar & Screed

Nanovations 3001 Hydrophobic Agent for Permanent moisture Protection for Concrete, Mortar & Screed

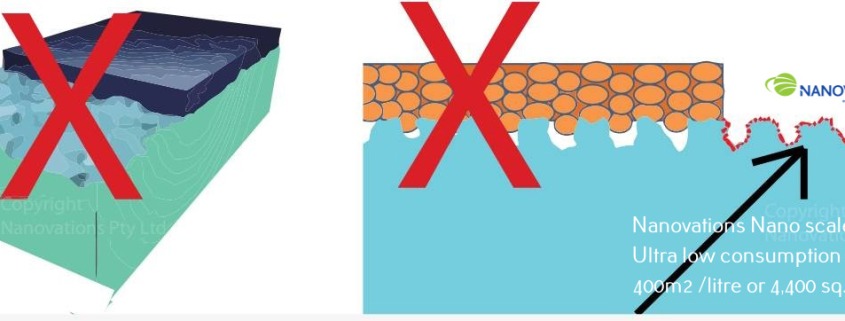

When it comes to protecting cement-based materials from water absorption, the industry has long relied on topical sealers only. While effective in the short term, these surface coatings have a fatal flaw: they are exposed to the elements.

UV radiation, foot traffic, abrasion, and harsh weathering inevitably break down surface treatments, requiring regular maintenance and costly re-application. Nanovations is changing the standard for durability with the 3001 Hydrophobic Agent—a solution that doesn’t just sit on the surface, but becomes part of the material itself.

The Integral Difference: Protection from Within

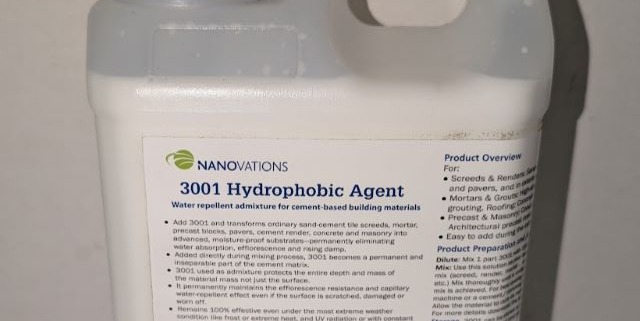

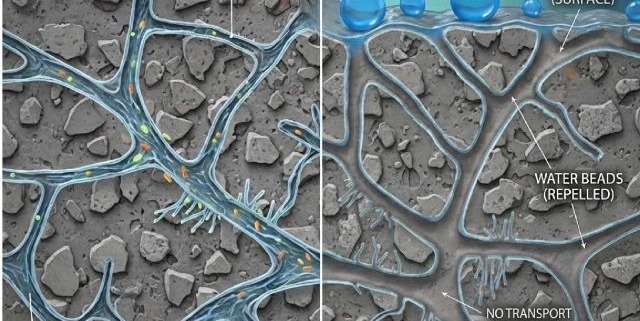

Unlike traditional sealers that form a vulnerable exposed layer on top of the substrate, Nanovations 3001 is a high-performance admixture added directly to the batching water. This method ensures the agent is distributed evenly throughout the complete mass of the material, providing integral protection for concrete, screed, or render.

By integrating the chemistry into the mix, the hydrophobic agent becomes a permanent part of the substrate’s mass material. This protection is not merely a “shield”; it is embedded into the matrix of the concrete itself. This means the water-repellent properties cannot wear off, peel, or degrade due to UV exposure or physical abrasion.

One Solution, Endless Applications

Because the 3001 admixture integrates with the cement hydration process, it is versatile enough to protect almost any cement-based product. It provides permanent hydrophobic protection for a vast range of construction materials, including:

The “Fit and Forget” Advantage

For architects and builders, the shift from topical sealers to integral admixtures offers a significant “fit and forget” advantage.

By locking the protection inside the material itself, Nanovations eliminates the risk of application error and the need for future maintenance. The result is a structure that resists efflorescence (salt blooming), rising damp, and water damage for the entirety of its life cycle.

Nanovations Pty Ltd continues to lead the Australian market in sustainable, nano-scale solutions. With the 3001 Hydrophobic Agent, they offer the construction industry a way to build cleaner, drier, and more durable structures—permanently.

Secure the longevity of your construction projects with the original, trusted hydrophobic admixture.

Ready to order? Visit our website to purchase directly. We offer door-to-door courier service for your convenience.

International clients: Please contact us or visit www.nanovations.com for global shipping options.

nanovation Pty Ltd

nanovation Pty Ltd Nanovations

Nanovations